WASTEWATER – EXHAUST GAS TREATMENT IN INDUSTRIAL FACTORIES

In the process of industrialization and modernization, factories play an important role in economic development. However, along with that development, a large amount of wastewater and emissions are generated, causing negative impacts on the environment and public health. Therefore, designing and operating an effective wastewater and emission treatment system that complies with environmental standards is a mandatory requirement for current production facilities.

1. Industrial wastewater treatment

1.1. Characteristics of industrial wastewater

Wastewater from industrial plants can contain components such as grease, heavy metals (Pb, Hg, Cd...), suspended solids, organic substances (high BOD, COD), acids - alkalis, toxic chemicals or microorganisms. Wastewater composition varies greatly according to the type of production: food processing, textile dyeing, paper, chemicals, metallurgy,...

1.2. Typical wastewater treatment process

An industrial wastewater treatment system usually includes the following steps:

- Primary treatment (mechanical): garbage separation, sand sedimentation, grease separation.

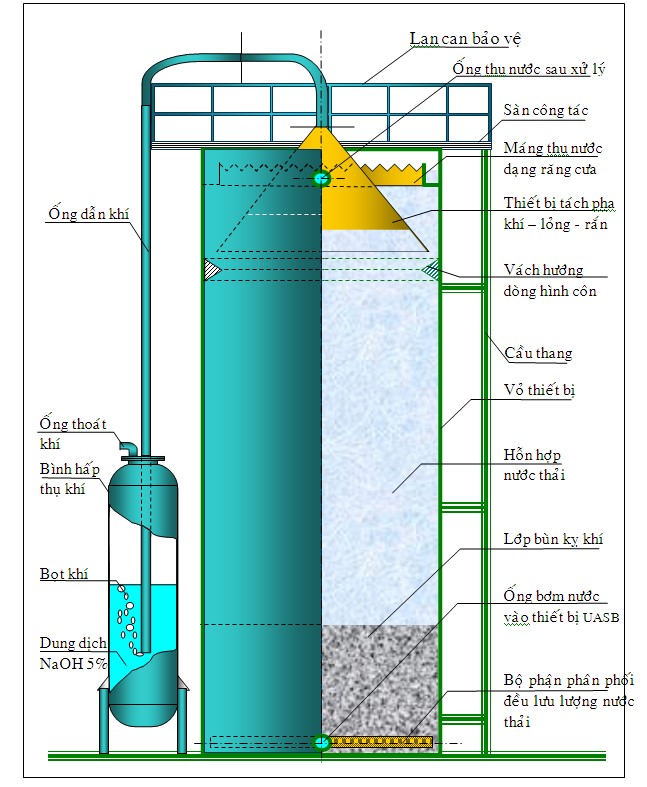

- Secondary treatment (biological): BOD, COD treatment by microorganisms (biological pond, Aerotank, MBR,...).

- Tertiary treatment (physical and chemical or membrane filter): removal of heavy metals, color, nutrients (N, P).

- Disinfection: by Chlorine, UV or Ozone before discharge into the environment.

1.3. Popular treatment technology

- Aerobic biological technology (Aerotank, MBR): highly effective for wastewater with high BOD.

- SBR system (Sequencing Batch Reactor): space-saving, flexible operation.

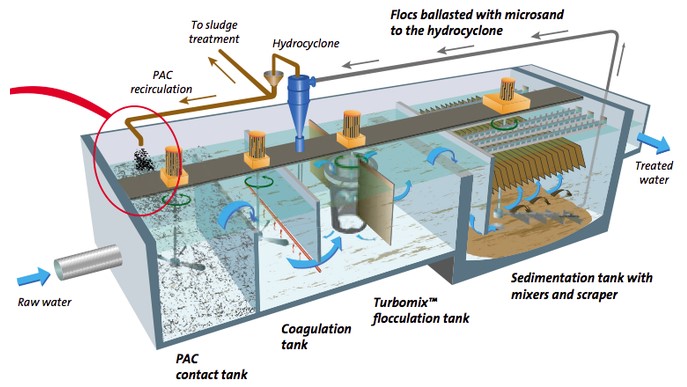

- Physical and chemical treatment: coagulation - flocculation, adsorption by activated carbon, ion exchange.

- Filter membrane (UF, NF, RO): deep treatment, reuse of water for production.

1.4. Discharge standards

According to QCVN 40:2011/BTNMT, industrial wastewater needs to be treated to meet the following criteria:

- BOD5 ≤ 30 mg/L;

- COD ≤ 75 mg/L;

- TSS ≤ 50 mg/L;

- Heavy metals at permissible threshold.

2. Industrial waste gas treatment

2.1. Characteristics of industrial emissions

Industrial emissions have a very diverse composition, depending on the production sector:

- Metallurgy, cement, brick and tile industry: generates a lot of fine dust, heavy metals, CO, CO₂ gas.

- Chemical and pharmaceutical industry: toxic gases such as NH₃, Cl₂, H₂S, VOCs.

- Textile and dyeing industry, food industry: bad odor, acid/alkaline vapor, VOCs.

- Thermal power industry: SO₂, NOₓ, CO, fly ash dust.

These gases not only affect the health of workers but also pollute the air in the surrounding area, reducing the quality of life of the community.

2.2. Methods of treating exhaust gas according to the nature of pollution

a. Dust treatment

- Settling chamber: reduces gas velocity, allowing dust to settle. Low efficiency, only used as a first step.

- Cyclone: uses centrifugal force to separate dust. Suitable for large dust (>10 µm).

- Bag Filter: removes fine dust, high efficiency (>99%).

- Electrostatic precipitator (ESP): uses electric field to precipitate dust. Suitable for high temperature gas.

b. Toxic gas treatment

- Scrubber tower: absorbs toxic gas into alkaline, acid or water solution. Used for SO₂, HCl, NH₃, H₂S.

- Thermal/catalytic oxidation: burns VOC gas at high temperature (700–850°C) or uses metal catalysts to decompose at lower temperature.

- Adsorption: uses materials such as activated carbon, zeolite to retain toxic gas and VOCs.

c. Deodorization

- Biofilter: gas flows through a layer of biological material with microorganisms to treat odorous gas (H₂S, NH₃).

- Ozonation: creates a strong oxidation reaction, breaks down odor-causing molecules.

- Deodorizing mist: uses odor-neutralizing solution, often used in waste treatment plants, food processing.

2.3. Design of exhaust gas treatment system

A basic industrial exhaust gas treatment system consists of the following parts:

- Gas collection system: hood, duct from the gas generation area to the treatment equipment. The design must ensure flow and avoid leakage.

- Treatment equipment: includes one or more devices such as cyclone, scrubber, ESP, ...

- Chimney: brings clean gas to the environment. The height is designed according to standards for safe gas dispersion (usually ≥ 15 m).

- Exhaust fan: ensures stable gas flow through the system.

2.4. Emission control and monitoring

Online monitoring equipment (SO₂, NOₓ, CO, PM2.5/PM10 dust) is required for large-scale factories.

Data is automatically transmitted to the Department of Natural Resources and Environment for continuous monitoring (according to Circular 10/2021/TT-BTNMT).

Periodic performance checks and treatment system maintenance should be performed every 3–6 months.

3. Comprehensive solutions and modern trends

3.1. Reuse and recycle resources

Waste treatment no longer stops at “cleaning before discharge”, but aims at reuse and recycling:

- Wastewater after treatment: can be reused for watering plants, washing roads, cooling equipment, supplying boiler water or fire fighting systems.

- ZLD (Zero Liquid Discharge) system: uses RO + crystallization evaporation technology to not discharge wastewater. Applicable to chemical, textile, and electronics factories.

3.2. Smart environmental management

- Automatic monitoring: set up sensors and SCADA systems to monitor pH, DO, flow, COD online.

- Failure warning: integrate SMS/email to warn when the system exceeds the pollution threshold.

- Integrate IoT + AI: predict pollution load and self-adjust chemicals/microorganisms.

3.3. Energy-saving solutions in treatment

- Using frequency converters (VSD) for pumps and fans: helps save 20–40% of electricity.

- Recovering waste heat from exhaust gas to heat water or dry materials.

- Using renewable energy such as solar power to support wastewater treatment systems.

3.4. Cooperating with professional treatment units

For small factories or those that do not have enough capacity to invest in their own treatment systems:

- Can sign a contract with an environmental company to receive wastewater, exhaust gas or sludge.

- This option helps businesses save on initial investment costs and still comply with the law.

Wastewater and exhaust gas treatment is a mandatory responsibility and also a part of the sustainable development strategy of industrial enterprises. Choosing the right technology, operating in the right process and strictly complying with legal regulations not only helps protect the environment, but also enhances the image and reputation of the enterprise in the market. In the future, treatment solutions towards reuse, energy saving and smart monitoring will be an inevitable trend.

INTRODUCING A REPUTABLE DESIGN & CONSTRUCTION CONSULTING SERVICE PROVIDER

The importance of construction units is undeniable, their reputation will ensure the quality and aesthetics of your project. Currently, there are many units providing design and construction services to meet the increasing construction needs in our country. Therefore, finding a reputable unit is not easy and requires you to spend time researching. In the selection process, you need to research carefully and ensure that the accompanying unit must have high expertise, many years of experience, have a clearly signed contract, transparent costs, ... To help customers save time searching, Hung Nghiep Phu Construction Investment Company Limited is confident that it will be the best choice for you.

Hung Nghiep Phu Construction Investment Company Limited with the mission of providing the best solutions and services, building a prosperous community with customers, Hung Nghiep Phu is gradually affirming its brand through sincere cooperation, with a leadership team with ethical capacity, creativity, high expertise and strategic vision. Hung Nghiep Phu owns a team of skilled, highly qualified employees who will bring customers the best quality technology.

Hung Nghiep Phu Construction Investment Company Limited - specializes in constructing civil and industrial works. We wish to accompany customers in construction projects as well as continuous procedures such as planning diagrams, applying for construction permits, completing procedures, applying for fire prevention and fighting certificates,... If you have any questions or are in need of design, completing procedures, please contact us immediately for free consultation!

>>> See more:

-

HOW TO ARRANGE COLUMN STEEL IN HIGH-RISE BUILDINGS TO ENSURE QUALITY

-

MOST POPULAR HOME RENOVATION AND REPAIR CONSTRUCTION METHODS

-

CONSTRUCTION METHODS OF ROUND COLUMNS FOR RESIDENTIAL HOUSES

_____________________

CONTACT INFORMATION FOR COOPERATION:

![]() Facebook: Công ty TNHH Đầu tư Xây dựng Hưng Nghiệp Phú (興業富)

Facebook: Công ty TNHH Đầu tư Xây dựng Hưng Nghiệp Phú (興業富)

![]() Hotline: 1800.3368 (free)

Hotline: 1800.3368 (free)

![]() Website: xaydunghungnghiepphu.com

Website: xaydunghungnghiepphu.com

![]() Gmail: kinhdoanh01@xaydunghungnghiepphu.com

Gmail: kinhdoanh01@xaydunghungnghiepphu.com

![]() Address: No. 2034D, Group 22, Phuoc Thai Hamlet, Tan Khanh Ward, Ho Chi Minh City

Address: No. 2034D, Group 22, Phuoc Thai Hamlet, Tan Khanh Ward, Ho Chi Minh City

------

Source: Compiled from the Internet