SHALLOW FOUNDATION SOLUTIONS FOR FACTORIES ON WEAK SOIL

In industrial construction projects, especially factory buildings, the foundation plays a crucial role in ensuring the long-term stability and safety of the structure. In Vietnam, many industrial zones are planned on areas with weak soil conditions such as soft clay, silt, or silty sand, which increases the risk of settlement, tilting, and structural damage if an appropriate foundation solution is not implemented.

In practice, shallow foundations are often prioritized due to their low construction costs, ease of implementation, and suitability for structures with moderate loads, such as factories. However, to apply shallow foundations on weak soil, appropriate technical treatment solutions must be used to enhance bearing capacity and ensure long-term structural stability.

1. Characteristics of weak soil in factory construction

Weak soil is characterized by the following features:

-

Low strength and bearing capacity

It has low shear strength, making it prone to sliding or settlement under structural loads.

It is unsuitable for directly transmitting structural loads without prior ground treatment. -

Large and prolonged settlement

Weak soil tends to undergo significant total and differential settlement, leading to cracked floors, foundation subsidence, and instability of machinery within the factory.

Settlement often continues over many years. -

Uneven compressibility

Causes differential settlement between columns or foundation areas, which can severely affect the structural integrity of the building. -

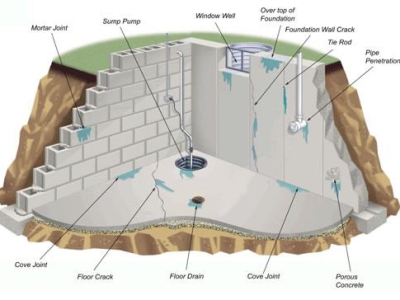

High groundwater level

Reduces the bearing capacity of the soil and makes foundation construction more difficult.

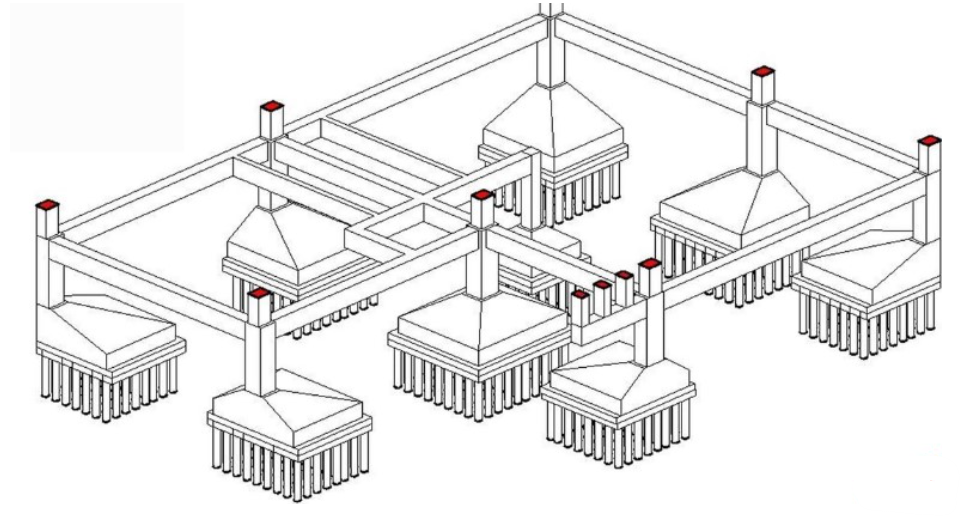

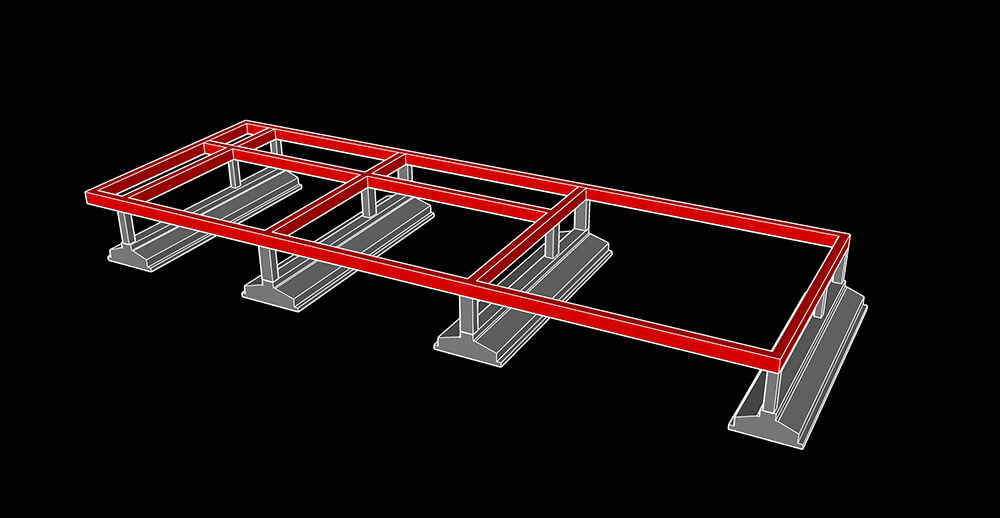

2. Types of shallow foundations used in factory construction

Common types of shallow foundations include:

-

Isolated (pad) foundation

Applied for factory columns with small loads, on soil with good strength or that has been improved. -

Strip foundation

Used when columns are moderately loaded and spaced close together. -

Raft (mat) foundation

Suitable for weak soil conditions where the load needs to be evenly distributed to minimize differential settlement.

In weak soil conditions, raft foundations are often the preferred choice due to their ability to distribute loads evenly and reduce ground pressure.

3. Ground improvement solutions for weak soil before shallow foundation construction

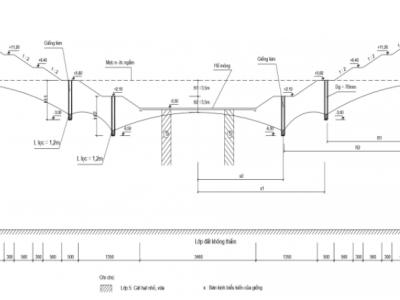

3.1. Replacing Weak Soil with Suitable Materials

Excavate the weak soil layer (typically 1–2 meters deep) and backfill with well-compacted medium sand, crushed stone, or high-density recycled materials.

Compaction must follow standard procedures, achieving a compaction coefficient K ≥ 0.95 (based on the Proctor compaction standard).

-

Advantages: Simple construction method, cost-effective if the weak soil layer is not too deep.

-

Limitations: Ineffective if the weak soil exceeds 2 meters in depth.

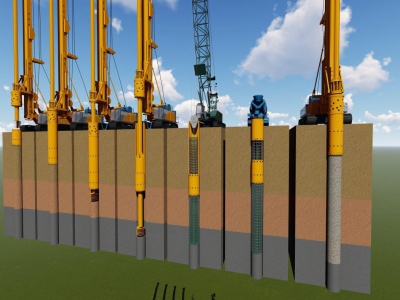

3.2. Ground Reinforcement Using Short Piles (Sand Piles, Bamboo Piles, Soil-Cement Columns)

-

Bamboo piles: Suitable for areas with high groundwater levels; soaked bamboo increases durability. Ideal for light-load structures.

-

Soil-cement columns: Drilled to depths of 3–6 meters, mixing cement grout with weak soil to improve the subgrade’s load-bearing capacity.

-

Advantages: Suitable for small to medium-scale projects.

-

Limitations: Requires strict construction control to avoid incorrect material ratios or improper mixing.

3.3. Preloading Combined with Prefabricated Vertical Drains (PVDs)

Install prefabricated vertical drains through the weak soil layer.

Apply preload using sand or clay for 1–3 months to increase pore water pressure and accelerate drainage.

-

Effectiveness: Accelerates settlement, shortens the time needed for soil stabilization.

-

Best suited for: Projects where immediate use of the building is not required.

3.4. Application of Geotextiles

Place geotextile fabric between the weak soil layer and the backfill layer.

Enhances load distribution capacity and reduces the risk of sliding or settlement.

Commonly combined with: sand cushion layers, crushed stone layers, or raft foundations.

4. Design and construction of suitable shallow foundations

4.1. Design of large footing slabs

Raft foundations are typically 30–50 cm thick and are reinforced with two layers of steel rebar.

They distribute loads evenly across the entire ground surface, thereby reducing contact pressure.

4.2. Integration of a Subgrade Drainage System

Install drainage channels, gravel drainage layers, or underground drainage systems to lower the groundwater level and improve the bearing capacity of the subsoil.

4.3. Construction Inspection and Monitoring Measures

-

Compaction check of backfill: Perform standard compaction tests or Standard Penetration Tests (SPT) to verify soil density.

-

Settlement monitoring: Install settlement markers during the preloading and operational phases to monitor actual ground movement.

-

Bearing capacity testing: Use plate load tests or test piles (if short pile reinforcement is used) to evaluate the subsoil’s actual load-bearing performance.

The application of shallow foundations in factory construction on weak soil is entirely feasible if appropriate ground treatment is implemented. Shallow foundation solutions not only help reduce costs and shorten construction time, but also suit structures with moderate loads such as manufacturing factories and warehouses.

The choice of ground treatment solutions should be based on geological characteristics, project scale, construction schedule, and investment costs. At the same time, strict compliance with design standards, inspection procedures, and construction quality supervision is essential to ensure the long-term effectiveness of the project.

INTRODUCING A REPUTABLE DESIGN & CONSTRUCTION SERVICE PROVIDER

The importance of construction contractors is undeniable—their reputation ensures both quality and aesthetics for your project. Currently, many companies provide design and construction services to meet the increasing construction demand in our country. Therefore, finding a reputable company is not easy and requires careful research. During the selection process, you must ensure the partner has strong expertise, many years of experience, clearly defined contracts, and transparent pricing, etc. To help customers save time, Hung Nghiep Phu Construction Investment Co., Ltd. confidently affirms itself as your best choice.

Hung Nghiep Phu Construction Investment Co., Ltd. with the mission of providing the best solutions and services, and building a prosperous community together with customers, Hung Nghiep Phu is gradually affirming its brand through sincere cooperation, led by a team of ethical, creative, highly skilled leaders with strategic vision. Hung Nghiep Phu possesses a team of well-trained and highly qualified staff who are committed to delivering the best quality technologies to clients.

Hung Nghiep Phu Construction Investment Co., Ltd. – Specialized in the construction of residential and industrial projects. We aim to accompany our clients throughout construction projects as well as related administrative procedures such as zoning plans, building permit applications, documentation completion, fire prevention and fighting certificate applications, etc. If you have any questions or need assistance with design or completing procedures, please contact us for a free consultation!

>>> See more:

-

HOW TO ARRANGE REINFORCEMENT STEEL FOR HIGH-RISE BUILDING COLUMNS TO ENSURE QUALITY

-

THE MOST COMMON CONSTRUCTION METHODS FOR RENOVATION AND REPAIR OF HOUSES

-

CONSTRUCTION METHODS FOR CIRCULAR COLUMNS IN RESIDENTIAL HOUSES

_____________________

CONTACT INFORMATION FOR COOPERATION:

![]() Facebook: Hung Nghiep Phu Construction Investment Co., Ltd. (興業富)

Facebook: Hung Nghiep Phu Construction Investment Co., Ltd. (興業富)

![]() Hotline: 1800.3368 (Free)

Hotline: 1800.3368 (Free)

![]() Website: xaydunghungnghiepphu.com

Website: xaydunghungnghiepphu.com

![]() Gmail: kinhdoanh01@xaydunghungnghiepphu.com

Gmail: kinhdoanh01@xaydunghungnghiepphu.com

![]() Address: No. 2034D, Group 22, Phuoc Thai Hamlet, Tan Khanh Ward, Ho Chi Minh City, Binh Duong Province

Address: No. 2034D, Group 22, Phuoc Thai Hamlet, Tan Khanh Ward, Ho Chi Minh City, Binh Duong Province

------

Source: Compiled from the Internet