SOUNDPROOFING SOLUTIONS – NOISE REDUCTION IN MANUFACTURING FACTORIES: ESSENTIAL REQUIREMENTS TO PROTECT HEALTH AND PRODUCTIVITY

Industrial noise is one of the most worrying issues in modern manufacturing environments. From stamping machines, presses, compressors, to industrial fan systems and continuous operation lines, noise levels in factories can exceed the allowable threshold, seriously affecting workers' health, reducing productivity and even affecting precision equipment.

At Hung Nghiep Phu Construction Investment Company Limited, we realize that soundproofing and noise reduction design needs to be implemented right from the planning and construction stage of the factory, and cannot be considered as a final auxiliary solution. This article comprehensively shares effective technical solutions that have been successfully applied in practice.

1. Harmful effects of noise in factories

Noise in production is not only a nuisance but also has many long-term consequences:

- Reduced ability to concentrate and work efficiency;

- Increased risk of work accidents due to not hearing warning signals clearly;

- Causing fatigue, hearing loss or ear-neurological diseases;

- Affecting precision equipment and automated lines;

- Reducing professional working environment, especially in factories with integrated office areas.

According to regulations of the Vietnamese Ministry of Health, the maximum allowable noise level in a continuous working environment is 85 dB (A). However, many mechanical, plastic, metallurgical, packaging manufacturing factories... often exceed this threshold if there is no suitable soundproofing solution.

2. Common sources of noise in factories

- Industrial machinery: stamping machines, cutting machines, grinding machines, air compressors;

- Drive equipment: conveyor belts, pumps, industrial fans;

- Ventilation - cooling systems: air ducts, high-capacity exhaust fans;

- Material collisions: objects falling on concrete floors, forklifts, pallets;

- Echoes from structures: walls, corrugated iron roofs, steel frames causing sound reflections.

These sources often resonate and amplify in closed environments such as factories, creating continuous noise and strong echoes.

3. Principles of soundproofing and noise reduction design

To effectively reduce noise, it is necessary to combine many solutions according to three basic principles:

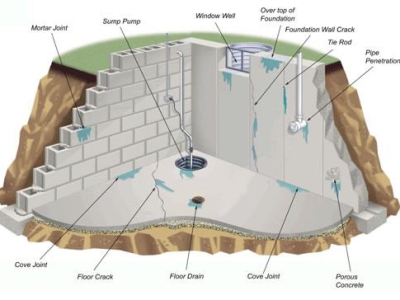

- Sound absorption: Use materials with porous surfaces and hollow structures to absorb sound instead of reflecting it. These materials are often installed on walls, ceilings or wrapped around noise sources.

- Sound barrier: Use solid, heavy and sealed structures to prevent sound from spreading from one area to another.

- Sound isolation and anti-vibration: Prevent sound from being transmitted through common structures or through vibration. Applicable to machinery systems, floors, partition walls and technical equipment.

4. Popular and effective technical solutions

4.1. Sound absorbing materials

- Mineral wool (rockwool), glasswool (glasswool): installed inside the wall or ceiling panel, fireproof and good sound absorption;

- Perforated sound-absorbing panels (perforated metal with sound-absorbing layer behind): used for technical ceilings or walls;

- Sound-absorbing foam (PU, PE, Melamine): light, easy to install, used around equipment;

- Sound-absorbing panels in the form of technical felt or sound-absorbing wood: used for office areas, control rooms in factories.

4.2. Soundproof panel system

- Walls and ceilings use EPS/PU/PIR panels with a thickness of 50–100mm, the middle layer is insulation and soundproofing material.

- Installed for integrated offices in factories, machine rooms, technical stations.

- Noise reduction capacity from 25–45 dB depending on the structure.

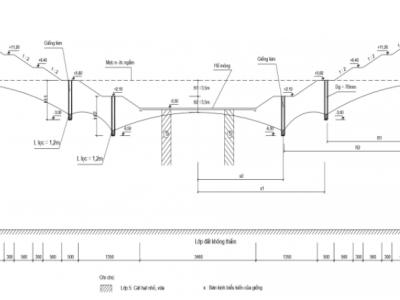

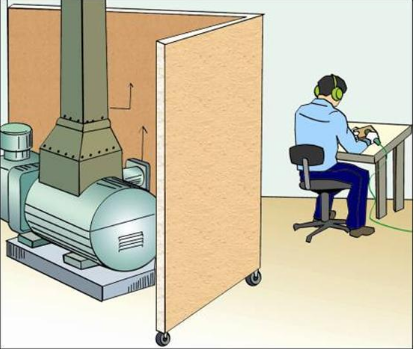

4.3. Local soundproofing machine room

- Build sealed chambers around machines that make loud noises (compressors, stamping machines, CNC cutting machines).

- The walls are made of multiple layers: corrugated iron - mineral wool - corrugated iron, with an additional layer of anti-vibration rubber.

- Double-layer soundproof glass doors, with airtight rubber gaskets.

4.4. Soundproofing roof and exterior walls

- The factory roof is covered with 3-layer insulated corrugated iron (corrugated iron - PU - corrugated iron) to reduce both rain noise and echoes in the factory.

- The surrounding walls use sandwich panels or bricks, plastered tightly, and are soundproof.

- Arrange a noise-proof louver system for areas with outdoor fan and ventilation equipment.

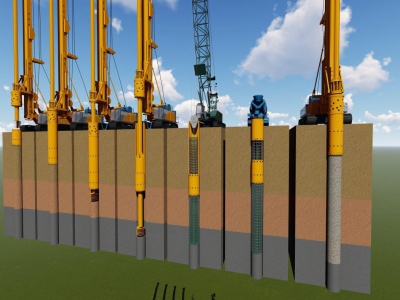

4.5. Vibration reduction – prevents transmission of mechanical noise

- Attach rubber shock absorbers or spring feet to vibrating machinery.

- Use soundproofing hoses when connecting fans and compressors to the piping system.

- Separate the structure of vibrating equipment from the main frame of the workshop.

5. Arrange production space reasonably to reduce noise

- Separate noisy machinery areas from inspection, packaging, and administrative areas;

- Design the flow of equipment and operations to minimize noise interference;

- If there is an office integrated in the workshop, separate soundproofing, soundproof doors, and isolated ventilation are required.

Soundproofing and noise reduction solutions are not only factors that create a comfortable working environment but are also mandatory requirements to ensure the health of workers and sustainable production efficiency. Especially for factories operating 3 continuous shifts, a quiet space with stable sound will help reduce work accidents and improve productivity.

Hung Nghiep Phu Construction Investment Company Limited is committed to providing optimal soundproofing design and construction solutions for each factory model. We not only build projects, but also accompany businesses in creating a safe, efficient and professional production environment.

INTRODUCING A REPUTABLE DESIGN & CONSTRUCTION CONSULTING SERVICE PROVIDER

The importance of construction units is undeniable, their reputation will ensure the quality and aesthetics of your project. Currently, there are many units providing design and construction services to meet the increasing construction needs in our country. Therefore, finding a reputable unit is not easy and requires you to spend time researching. In the selection process, you need to research carefully and ensure that the accompanying unit must have high expertise, many years of experience, have a clearly signed contract, transparent costs, ... To help customers save time searching, Hung Nghiep Phu Construction Investment Company Limited is confident that it will be the best choice for you.

Hung Nghiep Phu Construction Investment Company Limited with the mission of providing the best solutions and services, building a prosperous community with customers, Hung Nghiep Phu is gradually affirming its brand through sincere cooperation, with a leadership team with ethical capacity, creativity, high expertise and strategic vision. Hung Nghiep Phu owns a team of skilled, highly qualified employees who will bring customers the best quality technology.

Hung Nghiep Phu Construction Investment Company Limited - specializes in constructing civil and industrial works. We wish to accompany customers in construction projects as well as continuous procedures such as planning diagrams, applying for construction permits, completing procedures, applying for fire prevention and fighting certificates,... If you have any questions or are in need of design, completing procedures, please contact us immediately for free consultation!

>>> See more:

-

HOW TO ARRANGE COLUMN STEEL IN HIGH-RISE BUILDINGS TO ENSURE QUALITY

-

MOST POPULAR HOME RENOVATION AND REPAIR CONSTRUCTION METHODS

-

CONSTRUCTION METHODS OF ROUND COLUMNS FOR RESIDENTIAL HOUSES

_____________________

CONTACT INFORMATION FOR COOPERATION:

![]() Facebook: Công ty TNHH Đầu tư Xây dựng Hưng Nghiệp Phú (興業富)

Facebook: Công ty TNHH Đầu tư Xây dựng Hưng Nghiệp Phú (興業富)

![]() Hotline: 1800.3368 (free)

Hotline: 1800.3368 (free)

![]() Website: xaydunghungnghiepphu.com

Website: xaydunghungnghiepphu.com

![]() Gmail: kinhdoanh01@xaydunghungnghiepphu.com

Gmail: kinhdoanh01@xaydunghungnghiepphu.com

![]() Address: No. 2034D, Group 22, Phuoc Thai Hamlet, Tan Khánh Ward, Ho Chi Minh City

Address: No. 2034D, Group 22, Phuoc Thai Hamlet, Tan Khánh Ward, Ho Chi Minh City

------

Source: Compiled from the Internet